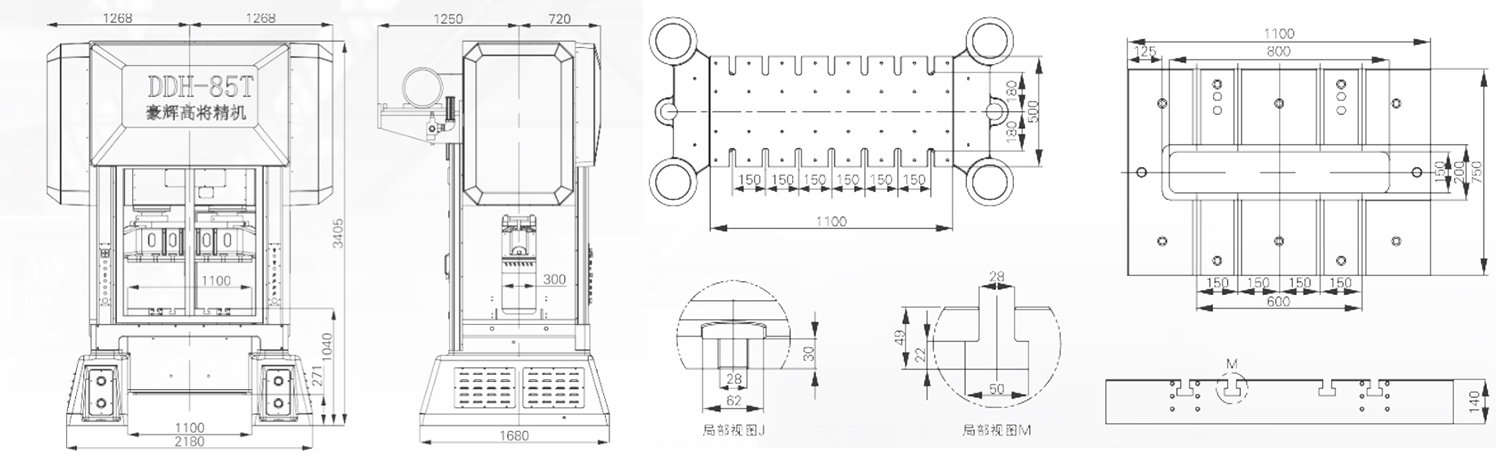

DDH-85T HOWFIT High Speed Precision Press

Lintlha tse ka sehloohong tsa tekheniki:

| Mohlala | DDH-85T | |

| Bokhoni | KN | 850 |

| Bolelele ba stroke | MM | 30 |

| Boholo ba SPM | SPM | 700 |

| Bonyane SPM | SPM | 150 |

| Lefu bophahamo | MM | 330-380 |

| Phetoho ea bophahamo ba lefu | MM | 50 |

| Sebaka se thellang | MM | 1100x500 |

| Sebaka sa Bolster | MM | 1100x750 |

| Ho bula bethe | MM | 950x200 |

| Ho bula bolster | MM | 800x150 |

| Enjene e ka sehloohong | KW | 22x4P |

| Ho nepahala | JIS /JIS Sehlopha se khethehileng | |

| Kakaretso ea Boima | TONANA | 18 |

Likarolo tsa mantlha:

● The foreimi e entsoe ka matla a phahameng a tšepe tšepe, e leng felisa khatello ea kelello ka hare ea workpiece ka nako ea tlhaho nako e telele ka mor'a taolo e nepahetseng mocheso le tempering, e le hore tshebetso ya workpiece ea foreime fihla boemo molemo ka ho fetisisa.

● Ho hokahanya ha foreimi ea bethe ho tlamisoa ke Tie Rod 'me matla a hydraulic a sebelisetsoa ho hatella mohaho oa foreimi le ho ntlafatsa haholo ho tiea ha foreimi.

● Clutch le mariki tsa karohano tse matla le tse hlokolosi li netefatsa boemo bo nepahetseng le braking e hlokolosi.

● Moralo o motle haholo oa ho leka-lekana, o fokotsa ho thothomela le lerata, 'me o netefatsa bophelo ba lefu.

● Crankshaft e amohela tšepe ea alloy ea NiCrMO, ka mor'a ho phekola mocheso, ho sila le ho sebetsa ka mokhoa o mong o nepahetseng.

● The non-clearance axial bearing e sebelisoa pakeng tsa silindara ea li-slide guide le molamu oa tataiso le ho bapisa le silinda ea tataiso e atolositsoeng, e le hore ho nepahala ho matla le ho tsitsitseng ho feta ho nepahala ho khethehileng, 'me bophelo ba setempe bo ntlafatsoe haholo. .

● Amohela tsamaiso e pholileng ea lubrication e qobelloang, fokotsa mocheso oa mocheso oa foreime, etsa bonnete ba hore boleng ba setempe, lelefatsa bophelo ba khatiso.

Sebopeho sa mochini oa motho se laoloa ke microcomputer ho hlokomela taolo ea ts'ebetso ea ts'ebetso, bongata ba sehlahisoa le boemo ba sesebelisoa sa mochini ka pono e hlakileng (sistimi e bohareng ea ts'ebetso ea data e tla amoheloa nakong e tlang, 'me skrini se le seng se tla tseba boemo ba ho sebetsa, boleng, bongata. le lintlha tse ling tsa lisebelisoa tsohle tsa mochini).

Boemo:

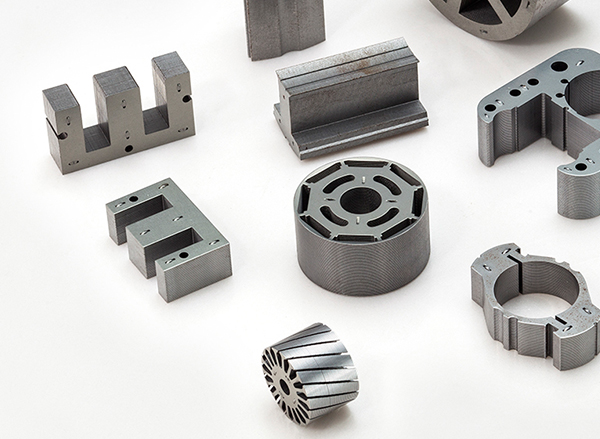

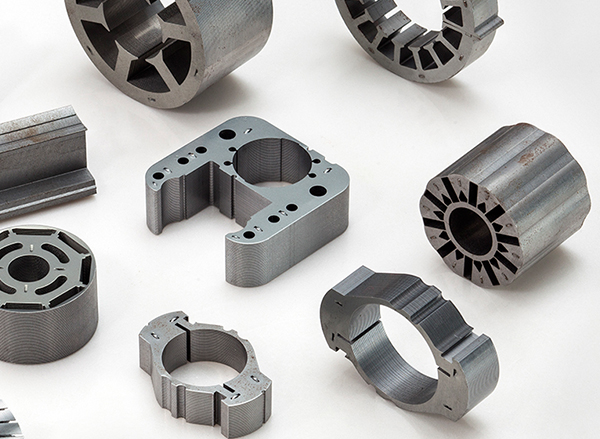

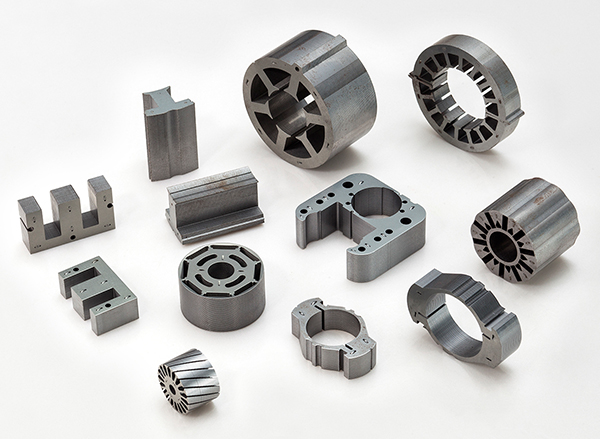

Tobetsa Lihlahisoa:

Ho ea ka Sebopeho sa Ts'ebetso ea Setempe e Tlang ho phethoa, boholo ba Batch ea 300 Tons High Speed Lamination Press, The Geometric size of the Stamping Parts (Botenya bo Koahelang, Hore na ke ho Otlolla, Sebopeho sa Sample) 'me Litlhokahalo tsa ho nepahala li khethiloe. :

> Likarolo tse nyane le tse mahareng li hlahisoa ka punch ea mochini o bulehileng.

> Punch ea mechine e nang le mohaho o koetsoeng e sebelisoa ho hlahisa likarolo tsa ho hatakela tse mahareng.

> Tlhahiso e nyane ea batch, tlhahiso ea likarolo tse kholo tsa poleiti e teteaneng e sebelisa mochini oa hydraulic.

> Tlhahisong ea bongata kapa tlhahiso e boima ea likarolo tse rarahaneng qalong, ho khethoa punch e phahameng ka lebelo kapa maemo a mangata.

Mochini o potlakileng le o nepahetseng oa Table Fan Motor Stamping ke molemong oa ona o moholo.

Ho bohlokoa haholo ho khetha Mochini o nepahetseng oa Tafole oa Fan Motor Stamping le ho felisa lihlahisoa tse ntle.Khetho ea pele ke ho taka litšoantšo tsa fin radiator, le ho lekanya boholo le botenya ba lihlahisoa.Botenya ba thepa e tala ke ho buleha ha hlobo.Khetha lithane tsa Mochini oa Setempe sa Tafole o loketseng radiator ea hau (Mochini oa Table Fan Motor Stamping ho latela boholo ba lihlahisoa tsa hau, ka kakaretso radiator e nyane ka ho fetesisa e hloka ho sebelisa lithane tse 45 tsa C-punch ea lebelo le holimo), le qetellong tlatsa thepa ea peripheral ea punch e lebelo le phahameng.